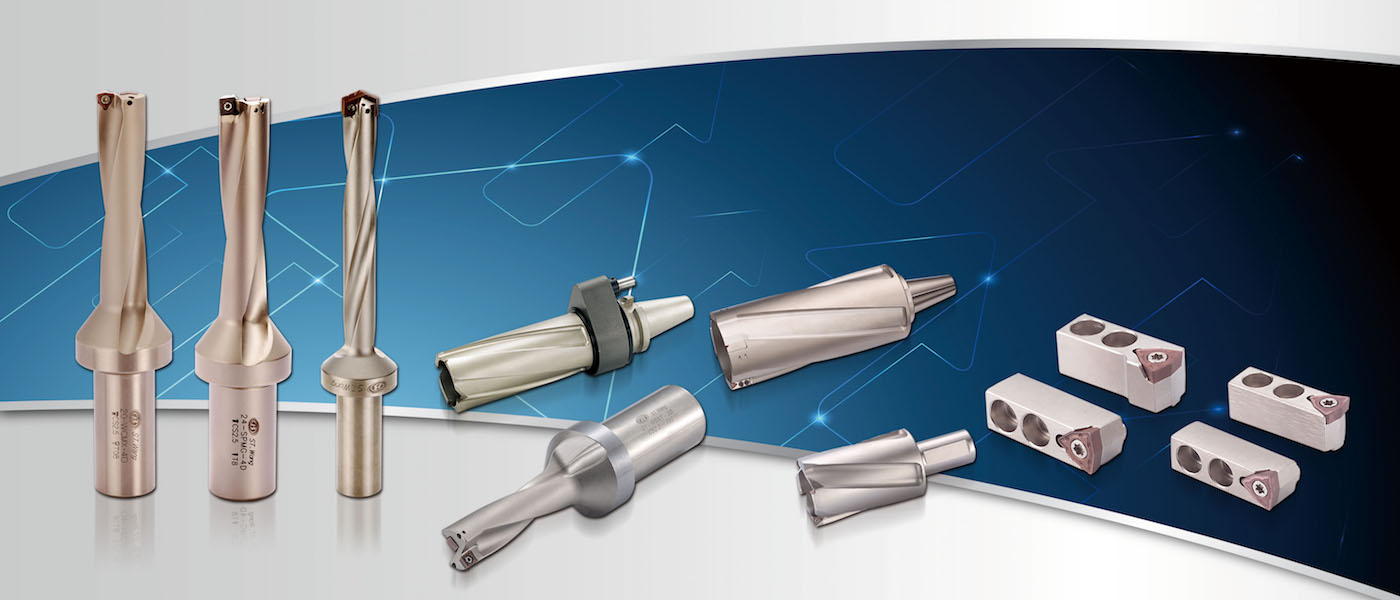

Machining is always about speed, precision and dependability, but in the highly competitive world of manufacturing efficiency is the most important factor. When you make components for the aerospace industry, automotive components or high-tech equipment the tools you select directly impact the bottom line. Indexable drills, high-speed drills, tungsten carbide end mills and threading inserts are essential.

Image credit: stwang-tw.com

They aren’t just upgrades to older software. These tools offer a better method of working, since they cut down on time and cost and produce higher quality results. We’ll look at the ways they can assist companies drill faster, cut cleaner and finish quicker.

Indexable Drills: More Holes, Less Hassle

Before recently, drilling huge holes was time-consuming and expensive. Solid drills often needed to be sharpened, wore quickly and caused a slowdown in the process. That’s why more machinists are switching to the indexable drill. When the tool becomes dull instead of having to replace the entire tool, you can simply change the cutting elements.

The effectiveness of indexable drills is the reason they stand out. They’re built to last, feature an extremely durable design, and require only minimal maintenance. Reduce loss, keep your tool inventory at a minimum, and prolong the life of your equipment by using replaceable inserts. SHANG TZANG WANG ENTERPRISE CO., LTD, offers modern core-stay drills for disposal that offer consistent performance for large-diameter applications. This upgrade reduces downtime for shops who perform repeated hole drilling.

High Speed Drills – Designed to Modern Demands

In a workplace where time is the most valuable commodity High-speed drills are designed to move fast without sacrificing precision. These drills work well with robust materials and quick cycle times. These drills are employed for everything from high-volume auto parts to precision medical devices.

Modern high-speed drills feature cutting-edge coatings and optimized flute designs to reduce friction and heat buildup and increase the lifespan of the tool. This means less breaks more tool replacements and a larger number of components. Switching to a high-speed drill is a fantastic option for any machine shop owner who has been through the frustration of an unfinished tool during the course of.

Tungsten Carbide End Mills: Reliable Performance Cut After Cut

In the realm of milling, tungsten carbide-based end mills are the mainstays of the shop floor. These end mills are famous for their heat resistance and toughness. They are also able to mill through tough materials without losing edge sharpness. When you’re roughing out huge sections or working on tight edges, these machines deliver reliable results that users can count on.

Their versatility is what really makes the tungsten carbide end mills special. They are able to be modified to meet different applications, from aluminum to titanium with different flute counts and the helix angles. For machinists who need both accuracy and durability, carbide end mills offer the perfect equilibrium between rough material removal and clean surface finishes.

Threading Inserts: Tiny Tools, Big Impact

Threads may seem to be just a small aspect of the process, but it’s one of the most crucial. A weak thread can damage an otherwise perfect part. That’s why a high-quality threading insert is crucial. These small, interchangeable tools are made to cut threads either on the outside or inside of the nut with precision and consistency.

Threading inserts, as opposed to conventional taps and dies that wear in different ways over time provide the same results. If one edge becomes dull it is easy to index to the next cutting edge without the need to take out the tool or re-grind. It is quick, cost-effective and easy to clean. Machine builders appreciate threading inserts, not only for their speed, but for their reliability. With the correct insert you’re assured that your threads will be perfect the first time, no subsequent passes, no rework, and no concerns about the possibility of part rejection.

The Bottom Line

In modern machining you cannot afford to waste time. So, today’s top-performing manufacturing facilities are shifting to intelligent, flexible tools. The cutting tools aren’t only more precise, they also simplify workflows and reduce changes, in addition to extending the useful life of the tool. What’s the outcome? The results? Less time spent on troubleshooting and more time is spent on producing precision parts. In a business with greater expectations and lower margins, manufacturers can be competitive through the use of tools that perform better.